19-03-2020

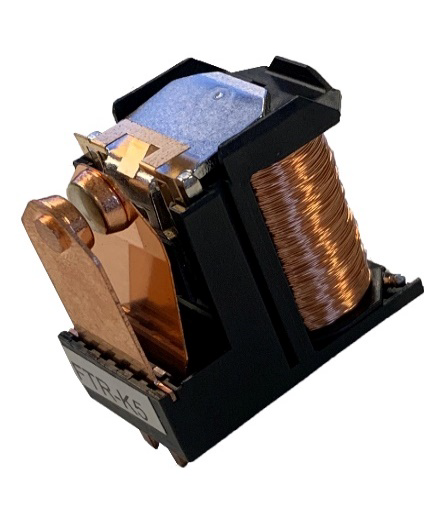

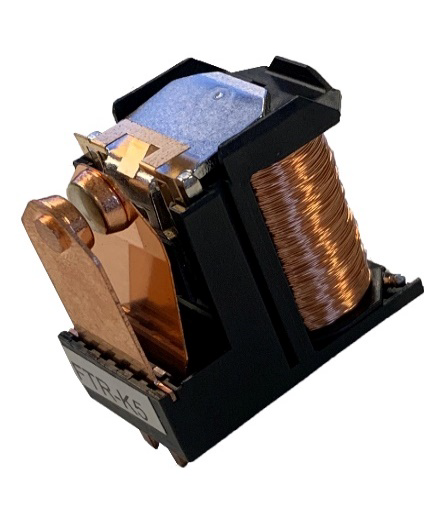

With e-mobility on the rise, so is the demand for specially designed components that cater to specific e-mobility needs. One obvious application is the charging of electrical vehicles, which relies on automotive grade relays as on-board gate keepers for increasingly powerful battery packs. Increasingly powerful, since modern e-driving, is all about range and charging times. This is why Fujitsu Components recently introduced the FTR-K5 series that, by doubling up on capacity, cuts charging times in half.

“We may not be the first,” Ben Schulte, marketing manager with Fujitsu Components admits, when asked about a new relay recently introduced by the company, “but as a supplier of automotive components for over a century and relying on robust Japanese production systems, FTR-K5 PCB relays are among the most reliable on the market. This especially holds true when considering the very compact design and high insulation class” (5000VAC).

More Power

The FTR-K5 relay is the second in a range of new EV (electrical vehicles) and PHV (plug-in hybrid vehicles) components that Fujitsu Components is currently developing for its e-mobility customers. Among them are manufacturers of e-cars e-trucks, e-boats, and other heavy-duty e-vehicles. Fujitsu’s first automotive-grade e-mobility relay for charging applications was the FTR-K1 - a 3.3 kW relay suitable for 16A and 250VAC - which was released in 2017. The new FTR-K5 version extends the range to 6.6 kW or 32A at 250VAC, cutting charging times in half by doubling the load specifications.

“In e-mobility there is a clear trend upwards when it comes to the power requirements demanded by the market”, Schulte explains. “One of the reasons, is that new-generation battery packs have a higher power-to-size ratio to allow a greater driving range. At the same time, e-vehicle and hybrid vehicle drivers want to spend less, rather than more, time at a charging station. Facilitating more power to be transferred in a shorter time effectively means, components such as on-board chargers and relays must be suitable for higher currents.”

Same Compact Design

Schulte adds that the new e-mobility relays, that are being developed to meet these requirements, obviously have to comply with the strict automotive standards concerning vibration resistance, operating temperatures, and insulation class, while simultaneously remaining as compact as possible. As always, available space is at a premium.

Schulte: ”We have managed to include an 8.8 mm creepage gap between coil and contact in a very compact enclosure with enhanced insulation, meeting all IEC61810-1 requirements. To increase reliability, a self-cleaning ‘wiping’ design of the contact points ensures a lifespan of 30,000 switching cycles and a continuous load of 40A.”

When asked if extending the range also means that we may expect ample more e-mobility relays from the Fujitsu factories in the near future, Schulte nods affirmatively. “I don’t want to get ahead of myself too much, but the next PCB relays in the FTR range are already under development. As a Japanese company, we may take our time in being thorough and getting things right, but once we commit, we stand by it. And I can assure you that Fujitsu Components is highly committed when it comes to serving the e-mobility market with best-in-class solutions!”

FTR-K5 Features

Fujitsu Components Introduces 6.6kW Relays for On-board Charging

With e-mobility on the rise, so is the demand for specially designed components that cater to specific e-mobility needs. One obvious application is the charging of electrical vehicles, which relies on automotive grade relays as on-board gate keepers for increasingly powerful battery packs. Increasingly powerful, since modern e-driving, is all about range and charging times. This is why Fujitsu Components recently introduced the FTR-K5 series that, by doubling up on capacity, cuts charging times in half.

“We may not be the first,” Ben Schulte, marketing manager with Fujitsu Components admits, when asked about a new relay recently introduced by the company, “but as a supplier of automotive components for over a century and relying on robust Japanese production systems, FTR-K5 PCB relays are among the most reliable on the market. This especially holds true when considering the very compact design and high insulation class” (5000VAC).

More Power

The FTR-K5 relay is the second in a range of new EV (electrical vehicles) and PHV (plug-in hybrid vehicles) components that Fujitsu Components is currently developing for its e-mobility customers. Among them are manufacturers of e-cars e-trucks, e-boats, and other heavy-duty e-vehicles. Fujitsu’s first automotive-grade e-mobility relay for charging applications was the FTR-K1 - a 3.3 kW relay suitable for 16A and 250VAC - which was released in 2017. The new FTR-K5 version extends the range to 6.6 kW or 32A at 250VAC, cutting charging times in half by doubling the load specifications.

“In e-mobility there is a clear trend upwards when it comes to the power requirements demanded by the market”, Schulte explains. “One of the reasons, is that new-generation battery packs have a higher power-to-size ratio to allow a greater driving range. At the same time, e-vehicle and hybrid vehicle drivers want to spend less, rather than more, time at a charging station. Facilitating more power to be transferred in a shorter time effectively means, components such as on-board chargers and relays must be suitable for higher currents.”

Same Compact Design

Schulte adds that the new e-mobility relays, that are being developed to meet these requirements, obviously have to comply with the strict automotive standards concerning vibration resistance, operating temperatures, and insulation class, while simultaneously remaining as compact as possible. As always, available space is at a premium.

Schulte: ”We have managed to include an 8.8 mm creepage gap between coil and contact in a very compact enclosure with enhanced insulation, meeting all IEC61810-1 requirements. To increase reliability, a self-cleaning ‘wiping’ design of the contact points ensures a lifespan of 30,000 switching cycles and a continuous load of 40A.”

When asked if extending the range also means that we may expect ample more e-mobility relays from the Fujitsu factories in the near future, Schulte nods affirmatively. “I don’t want to get ahead of myself too much, but the next PCB relays in the FTR range are already under development. As a Japanese company, we may take our time in being thorough and getting things right, but once we commit, we stand by it. And I can assure you that Fujitsu Components is highly committed when it comes to serving the e-mobility market with best-in-class solutions!”

FTR-K5 Features

- Switching capacity 32A@250VAC

- Operating ambient temperature -40 to 105°C

- Coil to contact creepage distance 8.8 mm, this meeting the IEC61810-1 enhanced isolation requirements (500VAC)

- 40A continuous current

- Available in plastic sealed and flux-free versions

- Manufactured under IATF16949 certification